|

|

|

After 19 awesome years, we've retired Utah Biodiesel Supply. For Stainless Filter Orders, For Pumps & Centrifuges, For Biodiesel chemicals & supplies, For BioPro Biodiesel Processors Cone Booster | Inline Heater | Heavy Duty Heating Elements | 8 Ft Power Cord Tired of making a mess? Want a better way to filter oil? Then it's time for a wvo centrifuge!!  We've teamed up with WVO Designs to bring you the simple-to-use and simple-to-clean wvo Raw Power Centrifuge. This centrifuge was designed by a mechanical engineer from the ground up to excel at filtering waste vegetable oil or waste motor oil in an easy manner. It's easy to use, easy to clean, and best of all, it works exceptionally well! Link to video With the power of up to 6,000 RPM's at your control, your dirty oil doesn't stand a chance! To test just how good 6,000 RPM's is, we picked up some of the nastiest oil that was obtained by an oil collector from a local McDonalds restaurant. The stuff looked really dark and smelled disgusting!

We hooked the wvo centrifuge up to a carboy of the nasty, smelly stuff, fired it up, and

let it rip! We let the centrifuge work it's magic on 5 gallons of the oil and compared the filtered vs non-filtered

samples of this smelly stuff.

To check the results, we grabbed a 100 micron bucket filter and put it in a 5 gallon bucket. We then poured the centrifuged oil through the filter to see just how much of the gunk it had removed. It poured right through the filter like water (see picture on left). Then we checked the bucket filter for any sediment and found nothing but an oily filter (middle picture below). Just to be sure the filter wasn't plugged, we put it back in place and poured the rest of the centrifuged oil through it. Again, it just flowed through it like water! Talk about impressive! Next, we grabbed some of the unfiltered oil and poured it through the same filter to see just how nasty the oil really was.

Get this! It wouldn't even go through our filter! (see picture on right) It just sat on top of the filter screen

plugging it immediately! We tried scraping the filter and sloshing the oil around,

but all we could get was a few drips and then it'd clog it right back up. We were amazed at the difference!

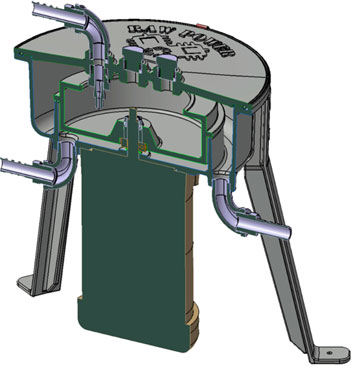

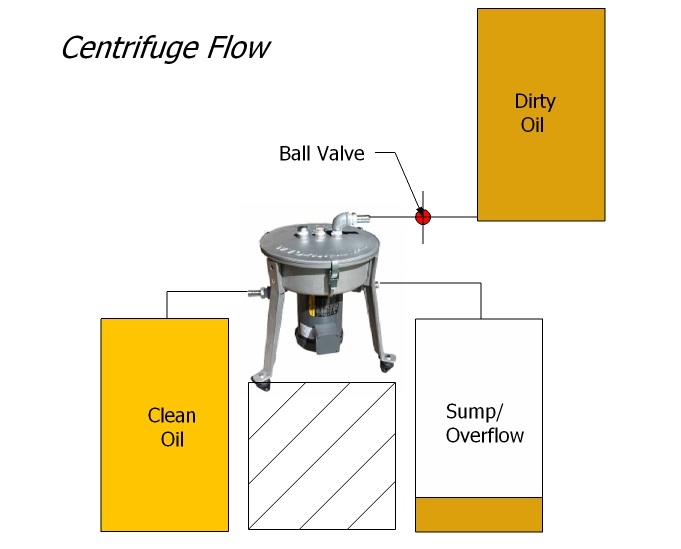

Forced Settling - Single Pass - Continuous Flow - Gravity Fed The dirt and water get trapped in the centrifuge bowl, while the clean oil sprays out over the top, collecting on the sides of the housing, then flowing out the drain tube. Link to video  Single Pass - Designed so you only need to run the oil through once No Fuss - No messy filters to buy, change, or monitor Quiet - Custom US Made Motor operates smooth and quiet (sounds like a large fan) Simply turn it on and let it run! A typical setup includes a container for the oil to draw from, a ball valve to control the flow, a container for the filtered oil, and a container for the bowl to drain into. Click here for some great examples of how customers have set up their Raw Power Centrifuges! Oil is fed into through the center port of the lid directly into the cone booster. The booster then gets the oil spinning prior to entering the centrifuge bowl. This reduces turbulance in the bowl and also keeps splashing to a minimum.   As seen below, the booster feeds the incoming/dirty oil into the bottom of the centrifuge bowl, forcing the dirty oil to have to work it's way through the entire batch of existing oil in the bowl.   Because of the booster's simple design, the centrifuge bowl can still be cleaned with the booster installed and makes the Raw Power Centrifuge even stronger! Click Here to see a great example of installing a booster in a legacy centrifuge bowl.

This sweet inline heater packs a punch! It utilizes a heavy duty 1,000 watt element that can be wired to use 120 or 240 volts and features an integrated thermostat that can be pre-set at any tempertaure between 60° F and 250° F. The housing mounts right to the centrifuge and includes a cover for the element and a heavy duty hose to connect it to the centrifuge lid. Because the oil flows from the bottom up, the element is sure to always be bathed in oil when filtering which means the oil stays hotter. In testing, we set ours at 150° F and it easily kept the oil up to temperature even when flowing at 15 gallons per hour. We especially liked the integrated thermostat! Talk about one slick unit! We thought of several other uses that it could be used for outside of just pre-heating oil for centrifuging. It comes with all the right mounting hardware and even a safety cap for the top to keep the electrical components tucked out of the way. We think it's well worth the additional cost. You'll love it the moment you power it up!

Based on the test we did with 5 gallons of oil filtered in about 20 minutes, we estimate we were running it through the centrifuge at 15 gallons per hour. Our test was based on a gravity feed with a carboy about 2 feet above the centrifuge and we didn't have any appreciable pressure pushing down on the oil, in fact we were fighting a vacuum on the carboy as the oil flowed out of it. You could easily get much higher flow rates simply with a larger volume of oil or by using a transfer pump. With it's ability to be pump fed or gravity fed, you can literally filter hundreds of gallons of oil quickly and easily and with relatively little effort on your part. Just connect the centrifuge to an oil input, pipe the good & bad oil output to the appropriate containers, turn the centrifuge on and let the oil flow! The centrifuge will do the rest.

WVO Designs has thought of everything to make building your Raw Power Centrifuge as easy as possible. In fact, the designer even created an incredibly easy to follow instructional video where he fully assembles a complete Raw Power Centrifuge from start to finish. You'll be impressed with how simple it is to build! With this great instructional video and included assembly instructions, you'll be up & running in no time! 30 Day Satisfaction Guarantee 1 Year Limited Warranty Limited Lifetime Warranty: Parts such as seals, bearings and clamps are warrantied for one year from the date of purchase. Please note that warranties do not apply to any parts or products which have been abused, misused, or damaged following incorrect installation or any use contrary to the instructions by the manufacturer or WVO Designs. Click Here To See Full Manufacturer Warranty Details Great Customer Service Like us, they're committed to your success. They want you to get the most out of your centrifuge and are there to help every step of the way. Don't believe us? Pick up the phone and give them a call or shoot them an email and watch how fast they respond! You'll be impressed! Raw Power Centrifuge Features & Benefits

Extreme Raw Power Centrifuge Upgrades Our Extreme Raw Power Centrifuge is different. Instead of just using a stock 3450 RPM motor and spinning it up to 6,000 RPM's, WVO Designs spent extra time and effort engineering a motor that was designed from scratch to handle the additional load. They worked directly with the manufacturer to develop a proprietary custom built motor that includes things like fully sealed motor bearings rated for 10,000 RPM's. In addition to the sealed motor bearings a shaft seal was also added as well as a final "slinger" seal as well. The motor itself also received some impressive upgrades which include cast iron end bells to help with rigidity and a bona fied factory rating plate for 6,000 RPM's with a rated service life of 20 years. With all these upgrades in place, you'll also notice that it runs quieter than a typical 3450 RPM motor as well. We call it "The Extreme Treatment" and you'll notice it the moment you pull it out of the box!

Additional Raw Power Centrifuge Resources We had so much information on the Raw Power Centrifuge that we couldn't realistically cram it all onto a single page, so below we've listed links to additional resources where you can learn more! Seal Installation Video Photo Galleries

Additional Videos

Customer Testimonials: See what those using the Raw Power Centrifuge say about it's cleaning power! “I've been using this CF with the pre-heater for about 8 months at the time of this review. I've cleaned over 1000 gallons of oil during that time, much of it during the winter. The pre-heater makes the CF hassle-free and the fit and finish of the unit is top-notch. I haven't had a single problem and the company's after-sale support is excellent. I wish I had started off doing it this way and had never messed with bag filtering.” - muns53 "Pure Awesomeness!" "This is definitely the best way to filter WVO, there is a lot less effort in the process and the oil comes out much cleaner than oil that has just been run through a normal filter. Customer service was also superb and after thousands of liters of oil and thousands of kilometers no WVO Designs product has ever let me down. Best company in the game for sure." - Dylan "Everyone should have one! "I just love this product. I went from changing filters on my truck about every 5000 km to now I get a min of 30,000 km and have done over 40,000 km. Not only does it save me buying bag filters but also the pain of getting under the truck to change the truck filter. I was doing 2,000 km a week so every 2.5 weeks was a pain on the side of the road." - Ian "WOW!!!!!!!!!! “Anyone interested in a used Diesel Craft Centrifuge CHEAP. After getting "WVO Designs" unit its all I need. I sell oil and no one has ever complained about dirty oil. It's a simple operating flawless tool I couldn't live with-out. I think it's the best oil cleaning product on the market. Its worth twice as much as your asking price. Thank you and I'm looking forward to more "WVO Design" products..." - The Green Guru Customer Installations:

Click Here To See Some Awesome Customer Pictures & Videos Of Centrifuges In Action We've packed it with several examples of how to get the most out of a Raw Power Centrifuge! Here's A Few More A group in Japan uses their centrifuge to remove Magnesol from Biodiesel with great success! Magnus in Australia purchased a centrifuge in early 2014 and uses it to clean vegetable oil for his diesels Kevin set up a complete Waste Motor Oil cleaning and dispensing system with his Raw Power Centrifuge. Christopher has a complete filtration system for cleaning and using Waste Motor Oil in a 6.5 liter GMC Turbo Diesel. Wade uses one of our centrifuges to filter new sunflower cooking oil. Click Here and Here and Here to see even more customer pictures & videos! CENTRIFUGE ASSEMBLY INSTRUCTIONS Want to see how easy it is to build a Basic or Extreme Raw Power Centrifuge? Then check out our great assembly instructions. They're included with every centrifuge and walk you through all of the steps to get your centrifuge up and running and filtering like a champ! Click here to download the factory centrifuge assembly instructions Additional Manuals: Centrifuge Component Specifications

|

|||||||||||||

|

MGBJ Enterprises, LLC - © Copyright 2005-2021 - All Rights Reserved - NX NEW |

||||||||||||||